On July 8, the four-day AMTS 2023 Shanghai International Automobile Manufacturing Technology and Equipment Exhibition concluded successfully at the Shanghai New International Expo Center. MEST keeps up with industry development trends and launches customized solutions and related product equipment for the fields of automotive electronics and new energy engineering, which are widely used in new energy vehicles, automotive electronics, consumer electronics and other fields.

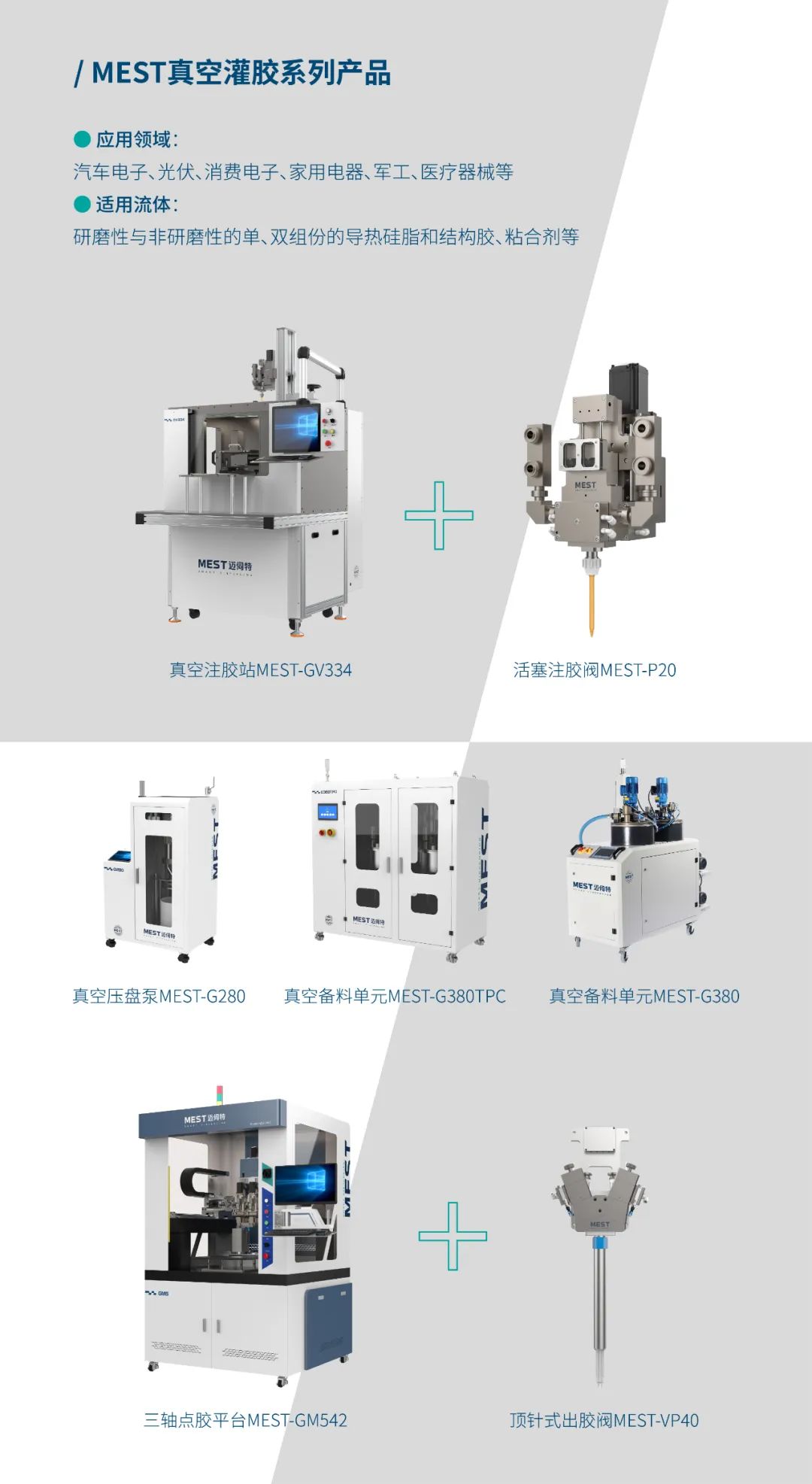

At this exhibition, MEST displayed a series of vacuum potting products for the automotive electronics field, including vacuum pail feeding system G280, vacuum system for self-leveling materials G380 and G380TPC, vacuum glue injection station GV334, etc., as well as a wealth of glue valves and controls. The series of products, including double-aisle screw valve FD2000, high viscosity screw valve F1000, etc., attracted many industry people to visit and negotiate.

▲Picture: MEST at the AMTS exhibition in Shanghai

At the automotive electronics assembly theme forum at the same time as the exhibition, MEST R&D Director Wang Weizhi gave an in-depth speech on the theme of "The Harm of Air Bubbles in Dispensing and Filling and How to Solve It" and interacted with the audience, which was very contagious. Through Wang's detailed explanation, the participants showed a strong interest in MEST's vacuum glue filling series products and looked forward to cooperation between the two parties.

Judging from data released by the Passenger Car Association, the national new energy vehicle market will maintain continued growth in 2023. The continuous launch of competitive new products is inseparable from technological upgrading and R&D innovation in the field of new energy vehicles. In this process, vacuum bonding, sealing, coating and potting are the key to achieving high safety and high quality of automotive electronic parts. The essential.

▲View: MEST on-site product display

The MEST vacuum potting system reliably ensures the reliability of glue filling quality in the face of complex product structures and small gaps. The vacuum system for self-leveling materials MEST-G380 performs glue pretreatment actions such as heating, stirring, and circulation within the vacuum pipeline to ensure a vacuum environment and isolate air during glue preparation and pressurized supply. The MEST-GV series of vacuum injection stations strictly ensures the vacuum operating environment. The glue is placed in the vacuum, and the stacked three-axis platform sends the glue to the piston injection valve MEST-P20 for high-precision dispensing operations, ensuring that the inside of the product is potting without bubbles.

As an expert in fluid application technology in China, MEST products are suitable for dispensing operations under various complex structures to ensure high-quality production results. For the challenges faced by customers in the automotive engineering field, our innovative technologies can greatly improve parts yield and production efficiency.

In future development, we will continue to adhere to the concept of "creating value for society", help enterprises realize intelligent transformation based on the entire product life cycle, and empower the "intelligent" manufacturing and upgrading of the automotive industry.