Us Now

Us Now

Us Now

Us Now

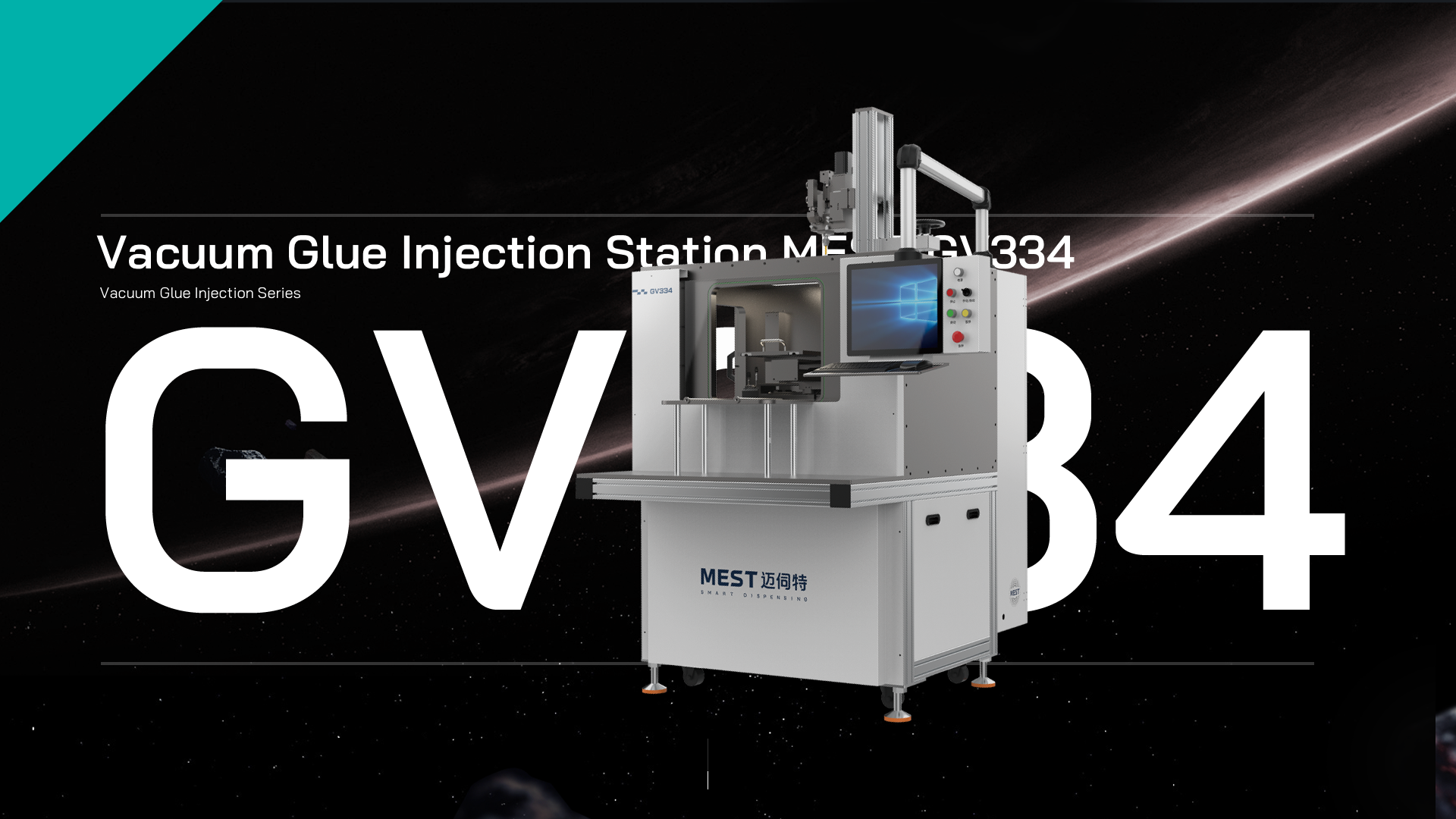

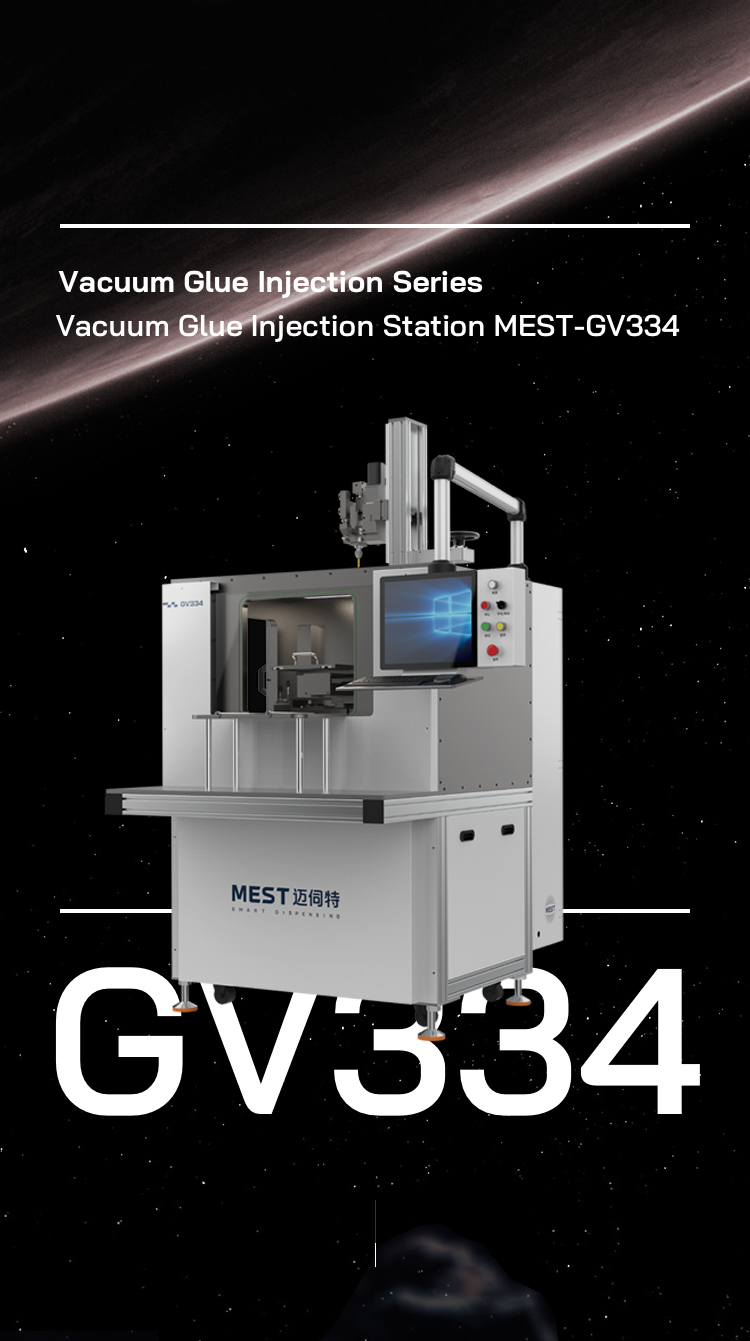

The vacuum glue injection station MEST-GV334 is suitable for products that have extremely high bubble requirements and need to be dispensed in a vacuum environment. With the vacuum material preparation machine independently developed and produced by MEST, and the piston glue injection valve P20, it can achieve single-head or multi-head simultaneous quantification. Potting ensures that the product is filled bubble-free, improving production efficiency while ensuring product quality. It can be specifically used in automotive electronics, photovoltaics, consumer electronics, household appliances, aerospace and navigation, deep water, military industry and other industries. In addition, it is more suitable for epoxy resin, polyurethane and silicone based fluids.

1. Vacuum potting: the glue and product are in a vacuum environment throughout the process, and the maximum vacuum can reach less than 2mbar

2. Reliability: Potting in a full vacuum environment improves product reliability and durability.

3. Modularization: All components are modular in design, making maintenance easy.

4. Humanization: The UI interactivity is extremely user-friendly and can be used in a variety of complex scenarios.

Overall size (mm) | 1600(W)*1250(D)*2500(H) |

Weight (kg) | ≈600 |

Working range (mm) | Customized |

Vacuum pail material and thickness (mm) | 6061/35 |

Control system | Industrial computer + motion controller + control software independently developed by MEST |

Maximum moving speed (mm/s) | 200 |

Machine load (kg) | ≤ 800 |

Maximum product size (mm) | 800*800*800 |

Vacuum degree (mbar) | ≤2 |

Power (W) | 12000 |

Input power | AC380V±10% 50Hz |

Gas source pressure (Mpa) | ≥ 0.55 |

Applicable ambient temperature (℃) | 0-50 |