Us Now

Us Now

Us Now

Us Now

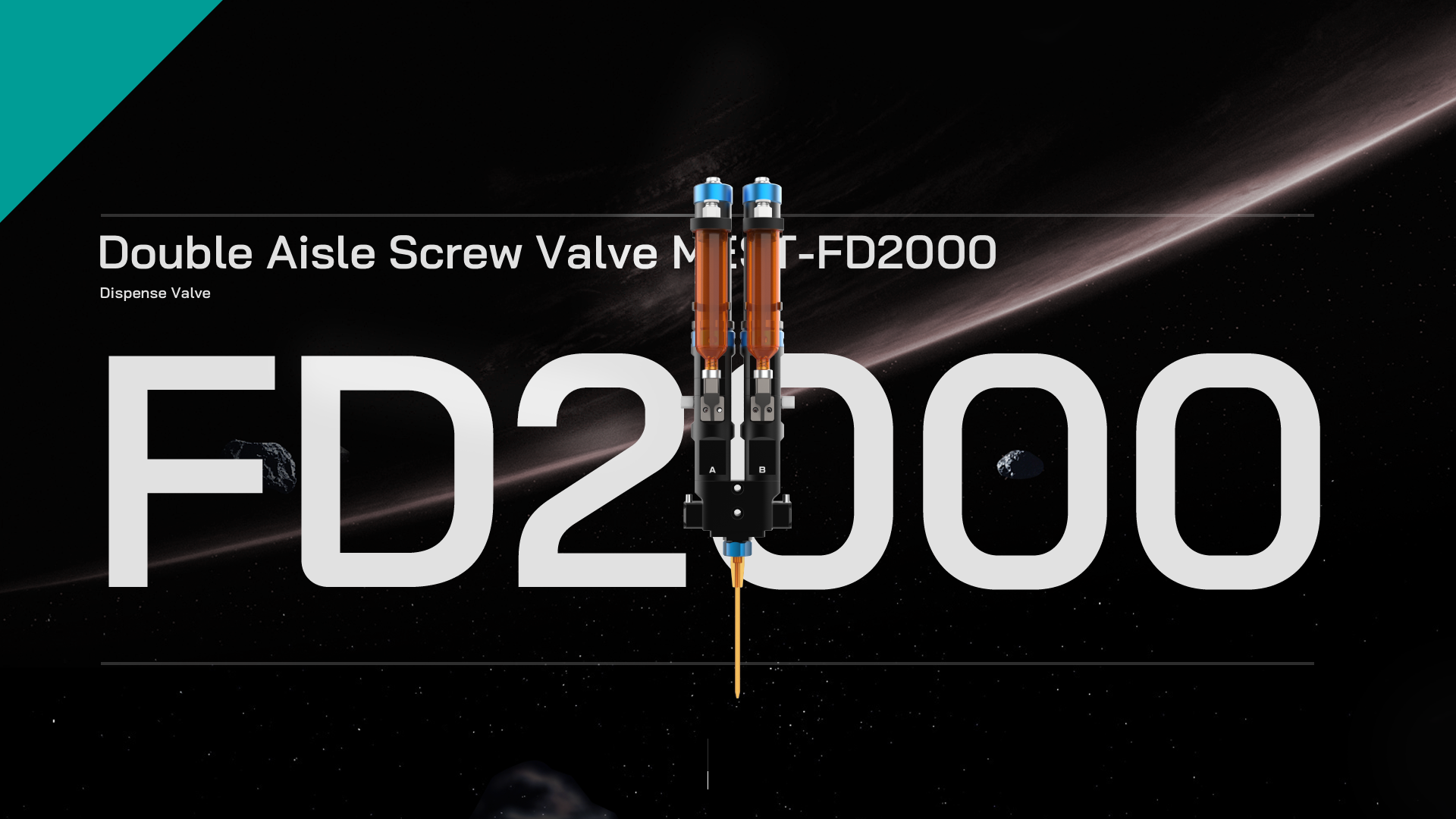

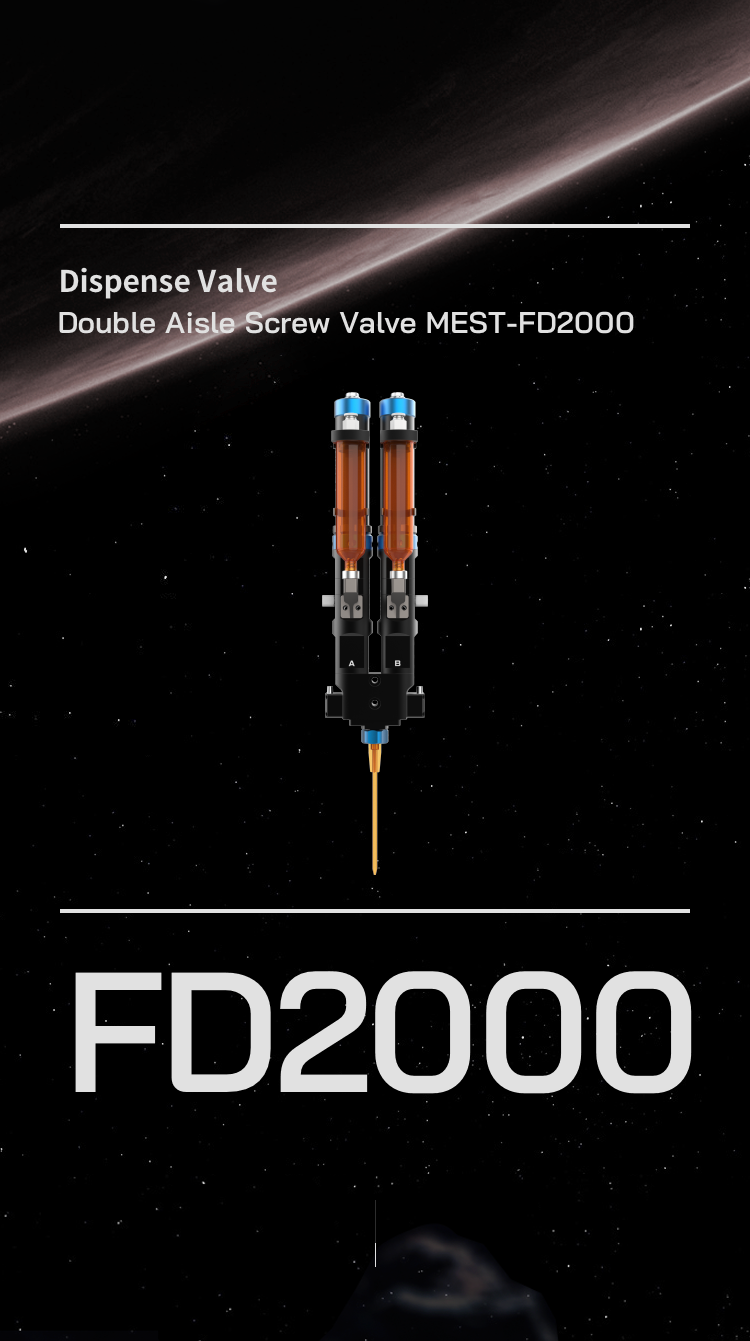

MEST-FD2000 is a contact-type double aisle screw valve that can control the flow and mixing ratio of various two-component adhesives and perform high-speed dispensing operations. Specifically used in automobiles, electronic appliances, aerospace, biotechnology, medical, food and other industries. Suitable for epoxy resin, polyurethane, silicone, conductive adhesive, ink, grease and other fluids.

1. Suitable for dispensing AB glue with low, medium and high viscosity

2. Adjust the speed of the two motors to quickly adjust the two-component dispensing ratio, which is simple to operate.

3. Precise output control and high dispensing repeatability

4. Dispensing accuracy ±1%/2ml

5. Adjustable suction to prevent back dripping, easily break glue and avoid string drawing

Specifications | FD2000-0.06 | FD2000-0.6-0.06 | FD2000-0.6 |

Overall dimensions (mm) | 32(W)*156(D)*310(H) | 45(W)*100(D)*370(H) | 45(W)*100(D)*370(H) |

Weight (kg) | 1.3 | 3.3 | 5.2 |

Suitable glue viscosity (CPS) | 0-500000 | 0-500000 | 0-500000 |

Mover material | SUS304 / zirconium oxide | SUS304 / zirconium oxide | SUS304 / zirconium oxide |

Stator material | FFKM / FKM / EPDM | FFKM / FKM / EPDM | FFKM / FKM / EPDM |

Inlet pressure (kgf/cm2 ) | 0~6 | 0~6 | 0~6 |

Dispensing consistency accuracy | ±2% | ±2% | ±2% |

Minimum dispensing amount (cc) | 0.05 | 0.05 | 0.05 |

Maximum dispensing volume (ml/s) | 0.24 | 1.32 | 2.4 |

Displacement (cc/r) | 0.12 | 0.66 | 1.2 |

Mixing ratio | 1/1 - 1/5 | 1/3 - 1/10 | 1/1 - 1/5 |