Us Now

Us Now

Us Now

Us Now

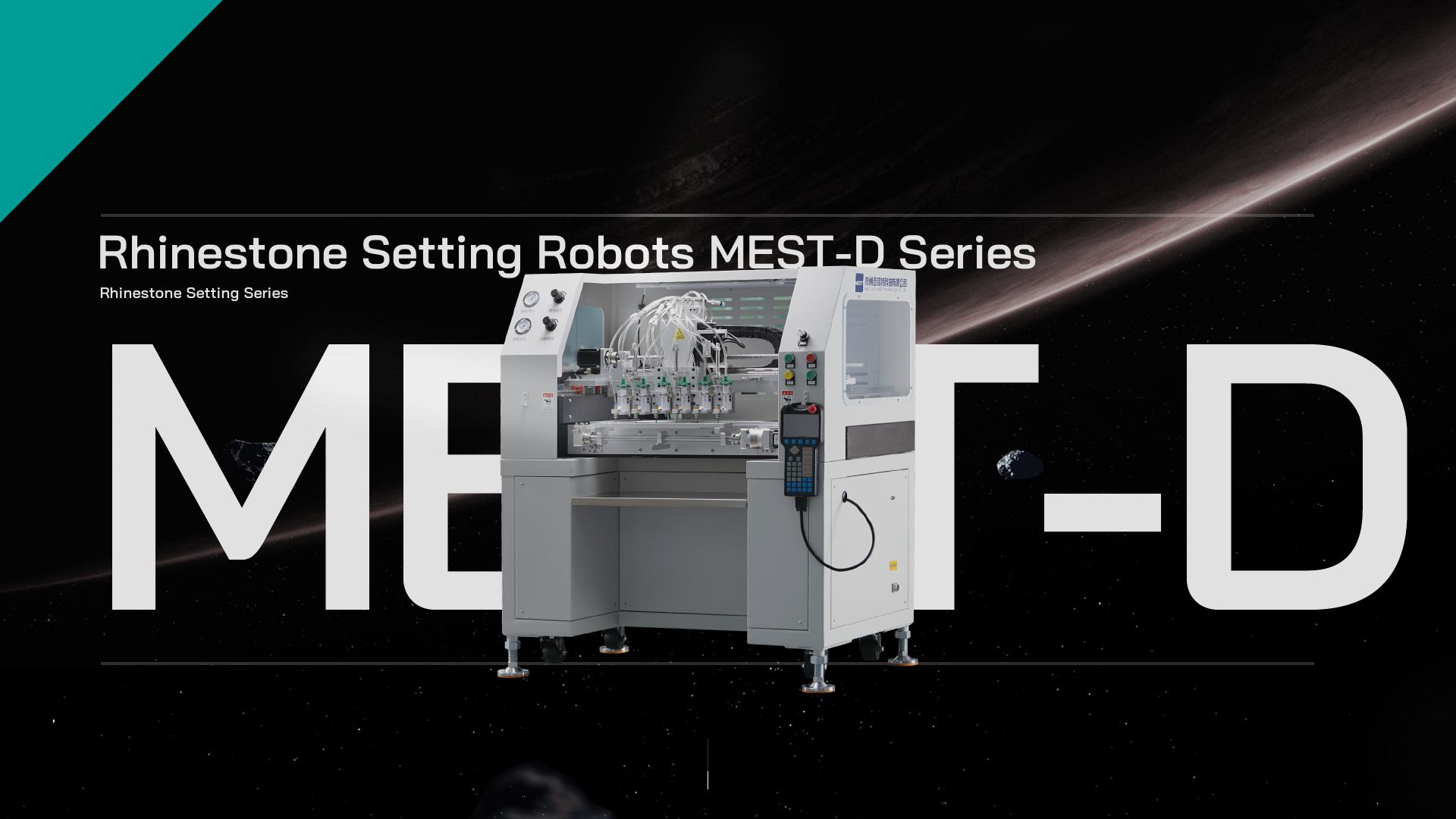

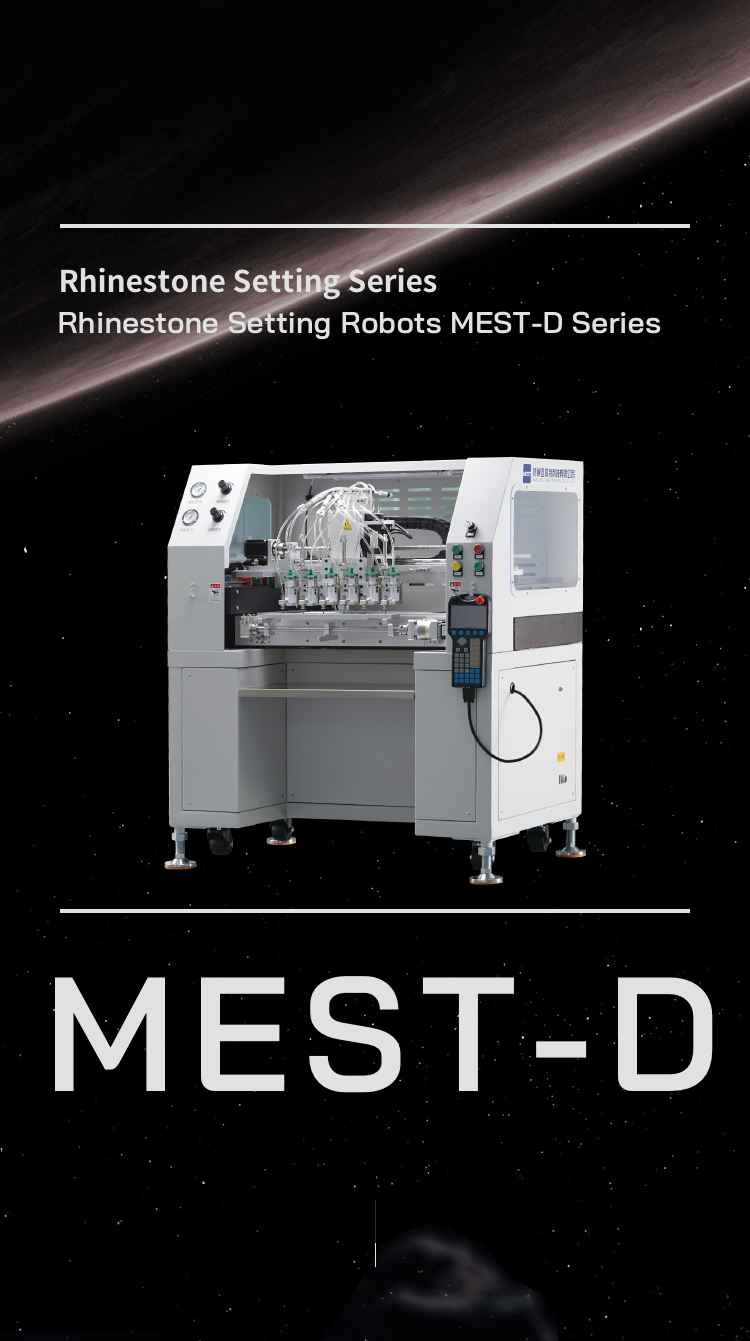

The Stone Setting machine has the characteristics of automatic bead suction and automatic setting. When the diamond moves to the product to be processed, ultrasonic waves are automatically generated, forming micro-amplitude and high-frequency vibrations on the rhinestone, which are instantly converted into heat to melt the material to be processed. Finally, the Setting is permanently attached or embedded on the surface of the product to be processed. The MEST-D series is a high-speed Stone Setting equipment independently developed by MEST. It can produce 10 heads at the same time and can produce up to 500,000 diamonds per day. It has high diamond placement quality, good glue consistency, and high diamond flatness. The equipment It can work 7*24 hours without stopping, with low failure rate and high production efficiency. This product is specifically used in products with rhinestones such as jewelry and clothing accessories.

1. The system can be upgraded. Special software can provide customers with free lifelong software upgrade services.

2. The equipment's user-friendly handheld programmer has a touch function, which is convenient, practical and easy to operate; the written programs can be copied between multiple machines. When multiple machines make the same product, they only need to be programmed once; the software has The array copy function of the rotation axis greatly shortens the operator's teaching and programming time when making curved products.

3. High stability: The equipment uses a marble base plate, which increases the counterweight of the equipment and provides good assembly accuracy for the whole machine; the XYZ three axes all use imported servo motors, which are stable, reliable, high-precision and have a long service life.

4. High cost performance. Large-scale standardized production reduces the procurement cost of parts and the assembly cost of the complete machine.

Model | MEST-D Series |

Overall size (mm) | 1100(W)*700(D)*1250(H) |

Product weight (KG) | ≈ 300 |

Stone Setting speed (CPH) | 40000(optimal conditions) |

Average speed (CPH) | 28000 |

Stone Setting accuracy(mm) | ±0.05 |

Type of Stone Setting | The software supports placement of no less than 20 types of stones |

Stone setting model | supports various Settings of No. 1 Setting and above |

Number of nozzles (pieces) | 4/6/8(supports customization of the number of nozzles) |

Nozzle spacing (mm) | 60/70(supports customization of nozzle spacing) |

Setting plate fixation method | Magnetic (left to right/ up and down) |

Main operating system | touch screen handle + Chinese and English operating system |

Control system | Industrial grade motion controller |

Drive system | servo motor |

Transmission mode | Precision guide rail + screw rod |

X/Y effective stroke (mm) | 480*440*90 |

Programming method | handheld programmer teaching programming / direct program import |

Working power supply | AC220V±10% 50Hz |

Rated power (W) | 1500 |

Working air pressure (Mpa) | ≥ 0.5 |