Us Now

Us Now

Us Now

Us Now

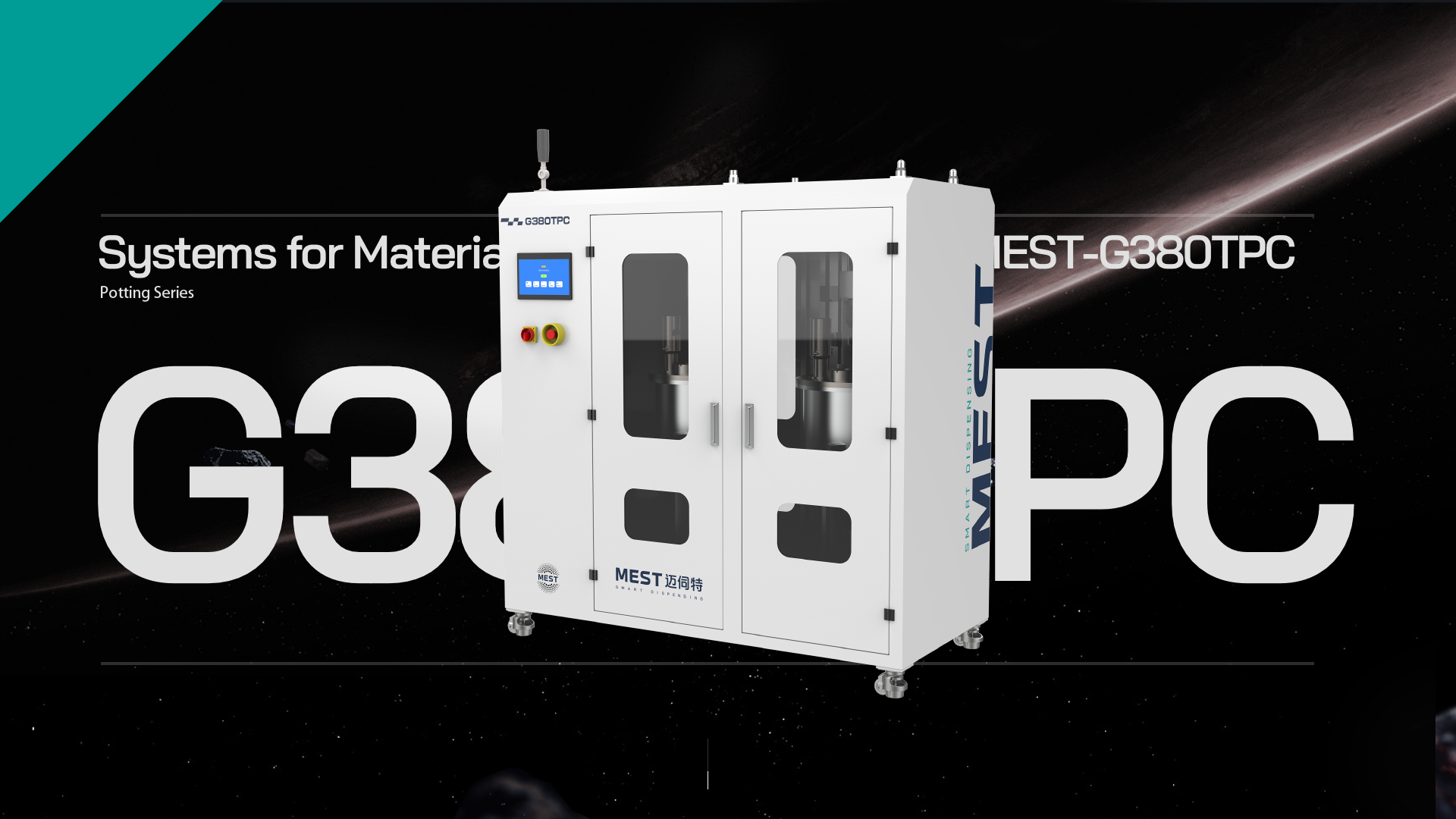

The G380TPC Systems for self-leveling materials independently developed and produced by MEST is used to handle sensitive materials with a high viscosity of 50000-100000 that will react with moisture or need to be prepared in a vacuum. It has functions such as heating, stirring, vacuuming and other glue pretreatment functions. It can be specifically used in industries such as automotive electronics, photovoltaics, consumer electronics, household appliances, aerospace and navigation, deep water, military industry and medical equipment. For example, transformers, ignition coils, controllers, electronic components, chip packaging, etc. In addition, it is suitable for single- and two-component epoxy resin, polyurethane, silicone and other fluids.

1. Vacuum feeding: the glue is in a vacuum environment throughout the process, and the maximum vacuum can reach 2mbar.

2. Non-stop: The equipment can supply materials without stopping, and glue can still be added normally during the working process.

3. Modularization: All components are modular in design, allowing users to quickly add or remove equipment functions and facilitate maintenance.

4. Humanization: UI interaction is extremely user-friendly and can be used in a variety of complex scenarios.

5. Durability: The specially designed piston pump structure has a long service life and is very suitable for glue with fillers.

Overall size (mm) | 1800(W)*850(D)*1900(H) |

Weight (kg) | ≈500 |

Control system | PLC + touch screen + control software independently developed by MEST |

Pressure paill specifications (L) | 80 |

Pressure barrel material | 304 |

Glue discharging method | plunger pump |

Glue feeding method | platen pump/pretreatment feed |

Applicable viscosity range (cps) | 50000-100000 |

Vacuum degree (mbar) | ≤2 |

Heating temperature (℃) | 25-100 |

Power (W) | 5000 |

Input power | AC380V±10% 50Hz |

Gas source pressure (Mpa) | ≥ 0.55 |

Applicable ambient temperature (℃) | 0-50 |