As a precision fluid manufacturer, MEST uses its excellent technical strength and continuous innovation spirit to continuously launch advanced dispensing equipment that meets market demand. In this issue, we will give you an in-depth understanding of the research and development background of the MEST panoramic vision dispensing machine, and discuss the technical highlights and application scenarios of this high-end product with R&D engineer Zhu.

Q1:When did you join MEST? What attracted you most to the company at that time?

I joined the company in June 2021. Mainly because of some people (which attracted me), including Mr. Peng, the R&D department, and the production workshop. The atmosphere is good and the relationship between colleagues is good.

This is a company that makes products. At that time, I felt that I would have a greater sense of accomplishment in the things I made here, and I should be able to do something better in a company like this.

Not all equipment companies can be as professional as MEST.

Q2:Do you personally think you have gained anything in the company over the past few years?

There are definitely gains, the product I am responsible for is getting deeper and deeper, and the competitiveness in the market is getting stronger and stronger. Customers are also more and more demanding, speed up at the same time to ensure stable quality,

but also to solve the process of some of the problems arising from the equipment, we go one by one to tackle it down. In the process of constantly solving problems to improve product quality.

Q3:Are there times when you feel tired or stressed? How did you face it?

Based on my work experience, it definitely does. For example, psychological stress may not be obvious now that you have experienced it too much, but it has become commonplace. Don't think too much and work hard. After a while, when a problem is solved, you will feel better.

Q4:What aspects stress you out? For example, during research and development, or when communicating with external parties.

Communicating with the outside world is not a problem. Generally speaking, I will definitely have a deeper understanding of the requirements of customers. I know what the tasks I do are to achieve. If you really want to do this work, it may not be easy to achieve.

You will make many plans, and you may fail. At this time, you are under a lot of pressure. You must keep thinking about how to achieve your goals.

Q5:Do you think the panoramic vision dispensing machine is a product that you are proud of?

The previous R&D engineers have already reached a certain level, and me taking over to solve emerging problems is just the icing on the cake or taking things to a higher level. You will definitely feel a sense of accomplishment as you become more and more perfect,

but you won't be too proud. When we were designing, we hoped to create a brand new thing, and the sense of achievement of being the first in China would be stronger.

Q6:What memorable things did you encounter during the model development process?

Every time I went to a customer site, I felt that it is difficult to perfectly meet customer needs through text description during plan design. Only by going to the site to see how they do it manually and what the final quality requirements are, can we better understand its (product) situation. Then we use the dispensing machine to do this to help manufacturers automate and intelligently The upgrade is quite good.

Q7:Let's talk about panoramic vision dispensing machine models. In what industries is it used for product manufacturing, and what fluid materials is it suitable for?

It is widely used in automotive electronics, 3C electronics, biomedical, security monitoring, aerospace and marine, semiconductor and hardware, jewellery, clothing accessories and other industries.

And is suitable for red glue, solder paste, silver paste, UV glue, one-component epoxy resin, electronic silicone, oil glue, ink, lubricant, crystal glue, thermal conductive adhesive, vinyl glue and so on.

Q8:Could you please give some specific examples?

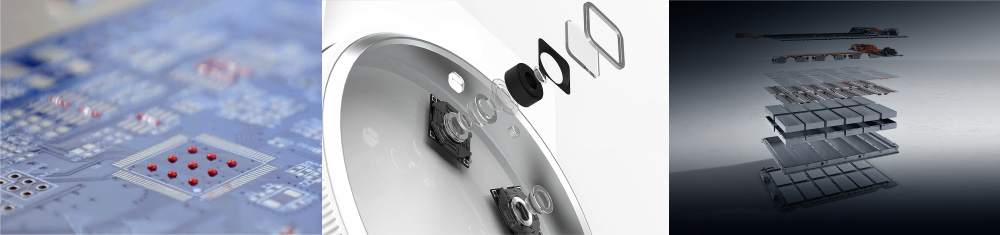

These are very common: If the circuit board is not potted, it will come into contact with air moisture and corrode the circuit board. Potting the circuit board completely isolates the air, ensuring product performance and extending service life.

In addition, the mobile phone camera can also be glued and bonded using a panoramic vision dispensing machine equipped with a screw valve to prevent the lens from falling off. There are also auto parts where you can use our machine to apply a trace of glue for cavity sealing and component bonding.

Q9:Why can the panoramic vision dispensing machine achieve high-precision dispensing?

The panoramic vision dispensing machine uses a high-definition camera, CCD detection, automatic needle alignment, and intelligent identification of product position. It can be automatically captured through the vision system for dispensing without manual positioning.

Optional dual vision system can position the product with secondary vision and capture the product outline with higher precision. In addition, through visual programming, the running trajectory can be customized, and the length, position, speed, height and working status of each movement trajectory can be programmed arbitrarily.

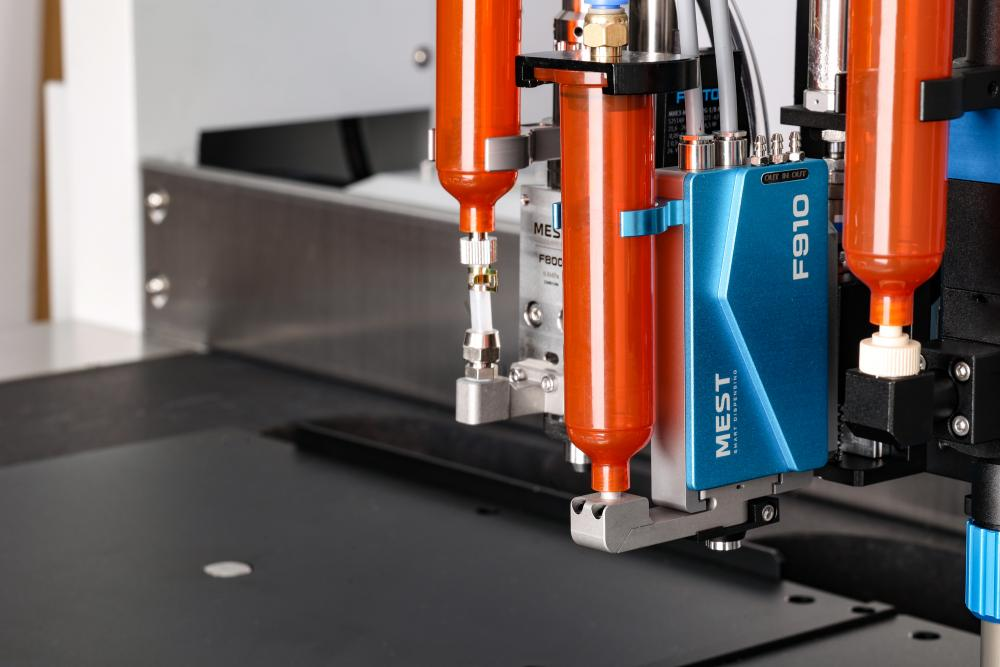

Q10:How many dispensing heads can we adapt to at most? What are the optional parts?

It can operate up to four heads, with single and double workstations optional. The double workstations work continuously, which greatly improves production efficiency. Depending on the needs, you can also choose the low liquid level automatic alarm mode, which is to install an out-of-position sensor in the glue barrel.

When the sensor senses that the glue is about to run out, it will sound an alarm and a flashing warning sign will pop up on our operation interface.