The first two issues of [Hardcore Labs] respectively introduced how Mesote solves the bubble problem in potting and the highlights of the vacuum material preparation&feeding system G380 in terms of functions and applications, whether it is the vacuum material preparation&feeding system G380 or vacuum potting. The system is inseparable from its good partner, the piston injection valve MEST-P20. In this issue, we have invited the R&D engineer of the vacuum potting system to introduce to you the core component MEST-P20.

Q&A

Q: Hello, could you please briefly introduce the piston injection head MEST-P20?

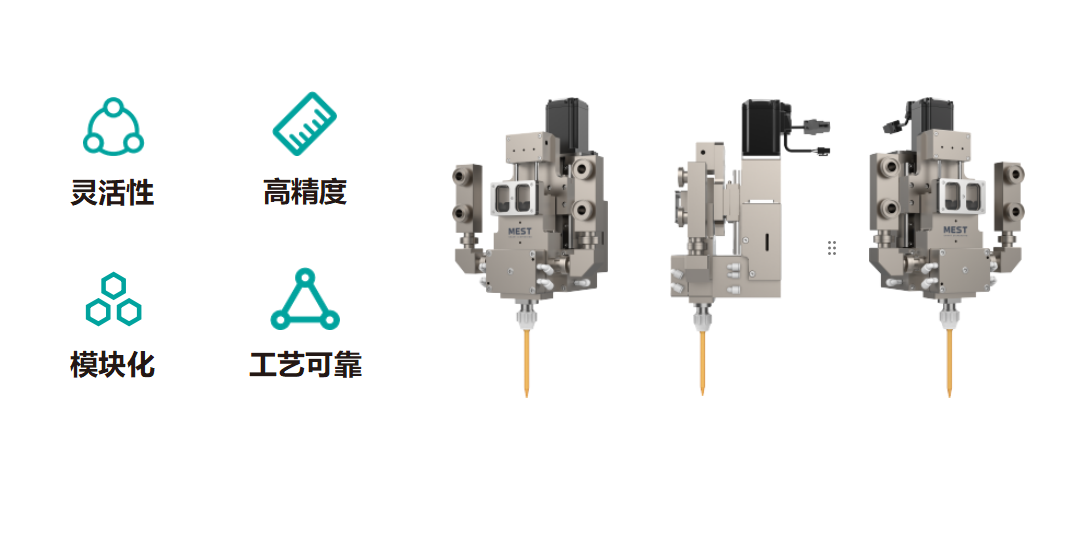

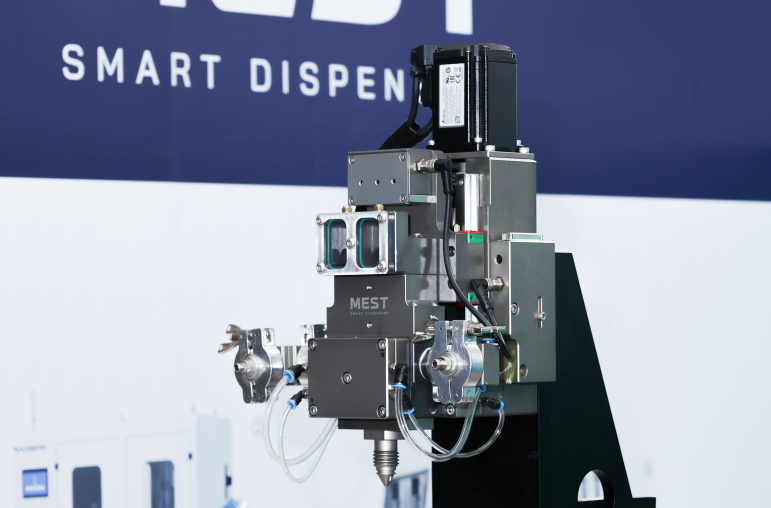

A:Okay, this piston dispensing head MEST-P20 is independently developed by MEST. Unlike screw valves and piezoelectric valves, our P20 piston quantitative volume dispensing head can ensure the consistency and accuracy of the dispensing process. Whether it is processing low to high viscosity, abrasive or non-abrasive single-component potting materials, it can handle them with ease.

Q: So, how does MEST-P20 achieve reliable and quantitative dispensing?

A:This involves an important point in our technology. Our piston glue injection head P20 adopts a piston volume quantitative method and adopts a feeding method of active potting, which can ensure the consistency of the glue volume filled inside the cylinder. Coupled with the vacuum material preparation&feeding system MEST-G380 independently developed by MEST, it can perfectly prepare materials and ensure uniform glue density for bubble-free. thereby ensuring that the quantitative volume of each cylinder is highly consistent.

After extensive testing, we can ensure a glue dispensing accuracy of ±2%. The minimum glue dispensing volume is controlled at 0.01 ml. The CPK at 0.0001 gram far exceeds customer needs, whether you need a micro-dispensing of less than 1 ml or hundreds of ml in a single time. For glue filling, this glue injection head can easily handle it.

Q: Are all components of MEST-P20 modular in design?

A:Yes, our entire vacuum potting series has the advantage of modular design. MEST-P20 is mainly composed of pneumatic module, quantitative and flow channel module, lubrication module and motion module. This design facilitates disassembly, assembly, and maintenance for customers, while also improving production efficiency and reducing costs. Our products are not only highly reliable and stable, but also flexible and scalable to meet the personalized needs of different customers.

Q: Why can MEST-P20 achieve high precision and high stability in dispensing?

A:P20 cooperates with the vacuum material preparation&feeding system MEST-G380 to steadily pressurize the glue through G380 to ensure the stability of glue dispensing. Moreover, we also adopt technologies such as perfect material preparation, active filling and volume quantification to ensure the accuracy of glue dispensing when the piston pushes glue.

In high-end industries such as automotive electronics, medical care, and biopharmaceuticals, the requirements for glue dispensing accuracy and stability are very high. These industries also have high requirements for the CPK of dispensing equipment. Our MEST-P20 runner module can perfectly control the CPK of dispensing.

Through professional runner module work simulation design, different proportions are adjusted for each size related to the runner in the module according to different glue ratios, dispensing amounts, and glue viscosity, so that each size can match properly. Ensure that MEST-P20 has a CPK value of ≥1.67 in any glue application, thereby achieving high-precision dispensing effects.

(Note: CPK is the abbreviation of Complex Process Capability index, which is an indicator used by modern enterprises to express process capabilities. Only with strong process capabilities can we produce products with high quality and reliability.)

Q: How does MEST-P20 ensure the correct ratio of two-component glue?

A:This isn't a problem with the P20. The MEST-P20 glue injection head accurately calculates the volume ratio of the glue through the glue TDS (Technical Data Sheet), then calculates the size of the two piston cylinders based on the glue output, and finally ensures the accuracy of the two cylinder liners through precision machining.

In addition, we also adopt the quantitative method of active potting and cooperate with the perfect material preparation of G380 to ensure that the glue is filled and flows in the cylinder liner and flow channel module in a uniform density and bubble-free form. Under the precision work of the servo motor, the glue is spit out from the MEST-P20 in perfect proportions, ensuring the correct proportion of glue.

Q: In which industries are MEST-P20 and vacuum potting systems used?

A:The P20 injection head is mainly used in industries such as automotive electronics, photovoltaics, 3C electronics, medical equipment and military industry, aerospace, deep water and deep sea where the product structure is complex and has extremely high bubble-free requirements, including IGBT modules, automotive electronic control unit modules and Aviation assemblies, etc. are all used.

For a more intuitive example, the ignition coil requires a vacuum potting system for insulation potting. If the potting is not done properly, there will be air bubbles between the wires, resulting in uneven thicknesses of copper wire insulation paint, causing instantaneous high and low voltages. Undesirable consequences of coil breakdown. Our vacuum filling system can perfectly avoid such problems, allowing customers to pursue excellent quality without worrying about air bubbles.

Q: What kind of after-sales guarantee do we have if we purchase MEST products?

A:In terms of after-sales service, MEST has a professional maintenance team and a complete technical support system to ensure that customers' equipment is always in the best working condition. Our maintenance team is composed of experienced technicians.

If customers need to replace parts or perform maintenance, we will respond promptly and provide corresponding solutions so that customers have no worries.