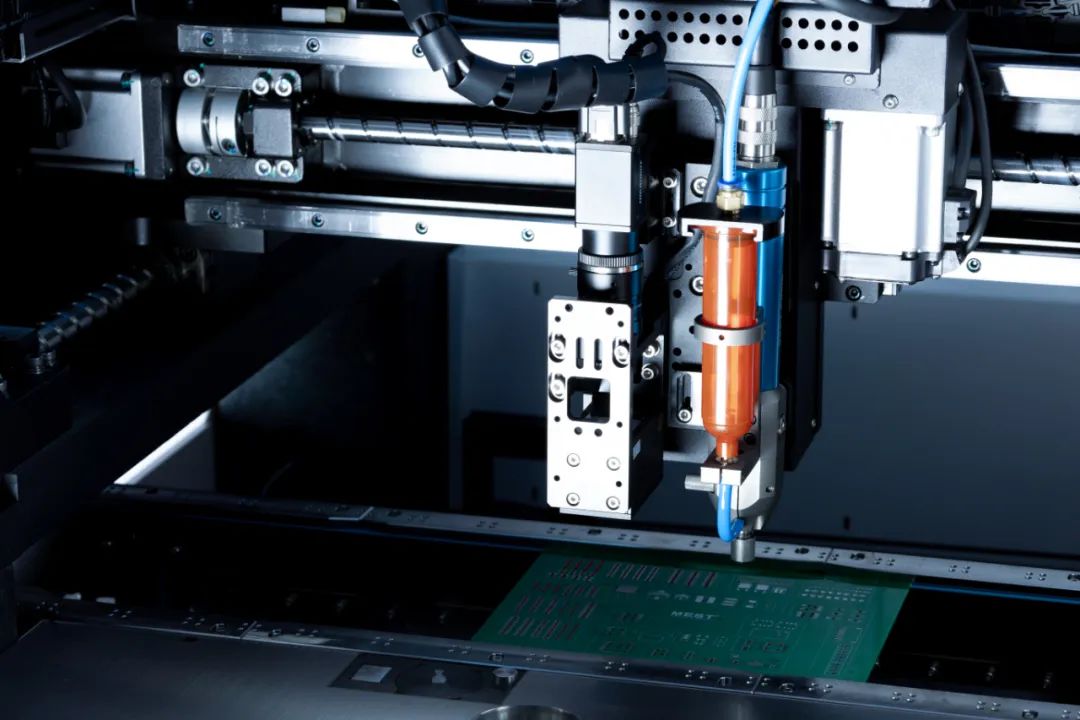

As a key component of fluid delivery, dispensing valves have an important impact on the functionality and stability of components and end products. With nearly ten years of technology accumulation and application experience, Mesote spares no effort to adhere to technological innovation and provide customers with high-quality valve products. Today, let us explore and discuss the application scenarios and dispensing advantages of screw valves with Mesote R&D engineers!

Q1:How to understand screw valve? Can we say the valve is like a faucet?

A:Not like this. The faucet itself does not generate power, it is just a channel with a switch that requires pressure from the front end. But the screw valve is different. It can generate pressure by itself. It is similar to a self-priming pump. It can output pressure and accept pressure. Even if there is no pressure in front, I can suck the glue over within a certain range.

Q2:As a R&D engineer, what do you find most interesting and challenging about your job?

A:There is a lot of pressure during the research and development process. It is not easy to make a product. This is not a matter of challenge. This has nothing to do with challenge. Our job is to build tall buildings on flat ground, it is not that simple. As for fun, I think it is a very personal thing. What is fun to me may not necessarily be fun to others. You still have to make some judgments and understand what you want.

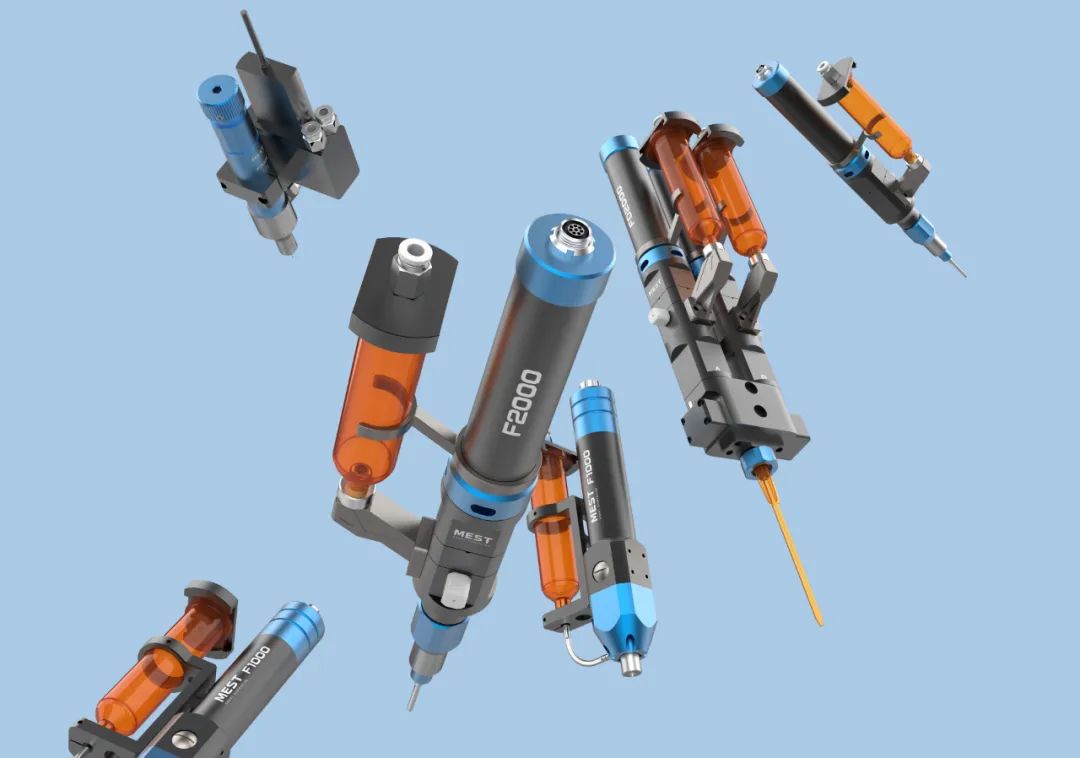

Q3:Closer to home, as the person in charge of screw valves, can you introduce the current three screw valves of Mesote?

A:Then let me explain it roughly.

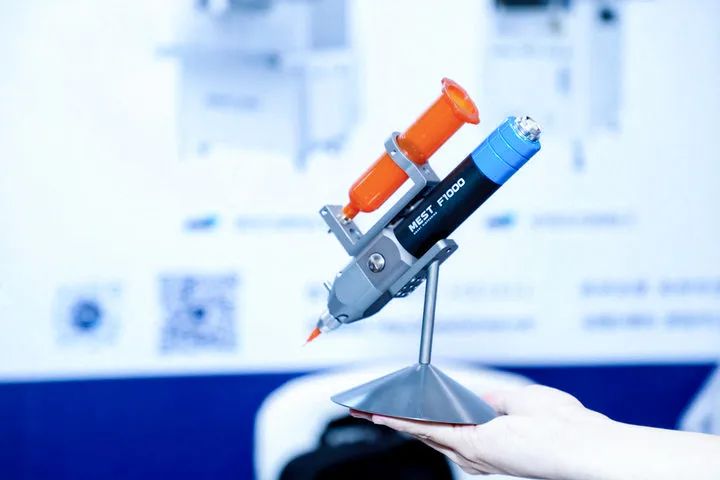

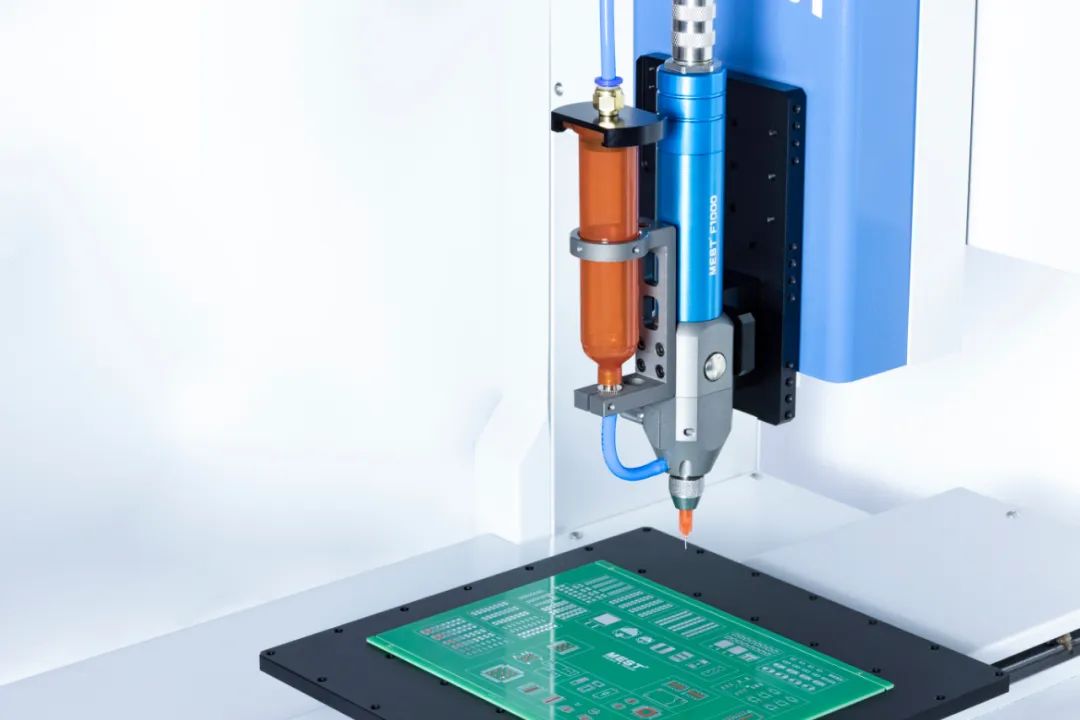

MEST-F1000 uses a carbide stator and rotor with good wear resistance. Because the stator and rotor fit together as a clearance fit, the valve itself does not have self-sealing properties, and the glue dispensing accuracy is slightly poor. It is only suitable for glue with a viscosity of more than 50,000 and with fillers, such as thermally conductive silicone grease, solder paste, etc.

The MEST-F2000 series uses a stator and rotor combination made of stainless steel and rubber. The stator and rotor fit is an interference fit. The sealing space created by the combination of the rotor and the stator can continuously and stably output pulsation-free glue through rotation. Theoretically, the glue viscosity can be ignored.

The MEST-FD2000 series is a combination of single-aisle valve bodies. It is mainly used for two-component glues of different proportions. The difference is that a glue pressure monitoring system is added to the glue outlet to prevent glue dispensing failures caused by accidental solidification after the glue is mixed. At the same time, it is convenient to quickly troubleshoot and solve problems.

Q4:In the manufacturing industry, what scenarios are screw valves suitable for? Can you give some examples?

A:The screw valve only exists as a screw. It is a kind of process. It depends on various aspects of cost performance and how the customer chooses. Screw valves with a displacement of less than 0.05ML are suitable for small output situations that require precise control of glue volume, such as waterproof strips for mobile phones (single-component), and the bonding of upper and lower shells of headphones (two-component).

There will be a waterproof strip on the frame of the mobile phone. In the past, a rubber ring was installed, but now a circle of glue is directly dispensed. After curing, a sealing structure is formed, which uses a small flow screw valve. If the earphone shell is bonded, it also needs to be bonded with glue. In this scenario, the total weight of the product needs to be controlled, so the amount of glue is also very stringent.

Screw valves with a displacement of 0.6ML or above are suitable for large output situations where the glue volume and ratio need to be precisely controlled, such as potting glue (two-component) for automotive radar boxes.

Q5:Are screw valves generally used in the energy storage and photovoltaic fields?

A:Then a large displacement (screw valve) is required. In the photovoltaic industry, the power connection box of solar panels, which is used in outdoor environments, must be waterproof and high-temperature resistant, so the entire circuit board is soaked in glue during production, similar to potting. The two-component screw valve is used at this time, and the spot welding glue will also use it.

▲ solar panel

Q6:What glues are suitable for screw valves?

A:Theoretically, the screw valve can ignore the viscosity and composition of the glue. Of course, the valve body material still needs to be adjusted in specific situations. For example, for anaerobic glue, the contact medium needs to be non-metal as much as possible, and the input and output ends of the valve body are made of PEEK.

Q7:What is the minimum dispensing volume of Mesote screw valve? Why can it achieve accurate glue output control and high glue dispensing repeatability?

A:Let me answer the first question first. The minimum dispensing volume of F1000 is 0.005ML, and that of F2000 is 0.0005ML. The displacement of the screw valve is determined by the stator and rotor, and there are various specifications to choose from. The accuracy of glue dispensing lies in the coordination of the stator and rotor and the accuracy of its processing equipment. The better the consistency of the internal structure, the higher the accuracy.

Q8:Why does the single-liquid screw valve have "adjustable suction to prevent back-drip"?

A:This statement is a method for the single-liquid screw valve to control the reverse rotation of the rotor to quickly cut off the glue after the normal dispensing is completed.

Q9:Do auger valves have the ability to be spot coated with packing or abrasive materials? If so, by what means?

A:It can be achieved, but the service life will be shortened! The method is to increase the gap between the stator and the rotor and change the rotor material, such as ceramics, cemented carbide, etc.

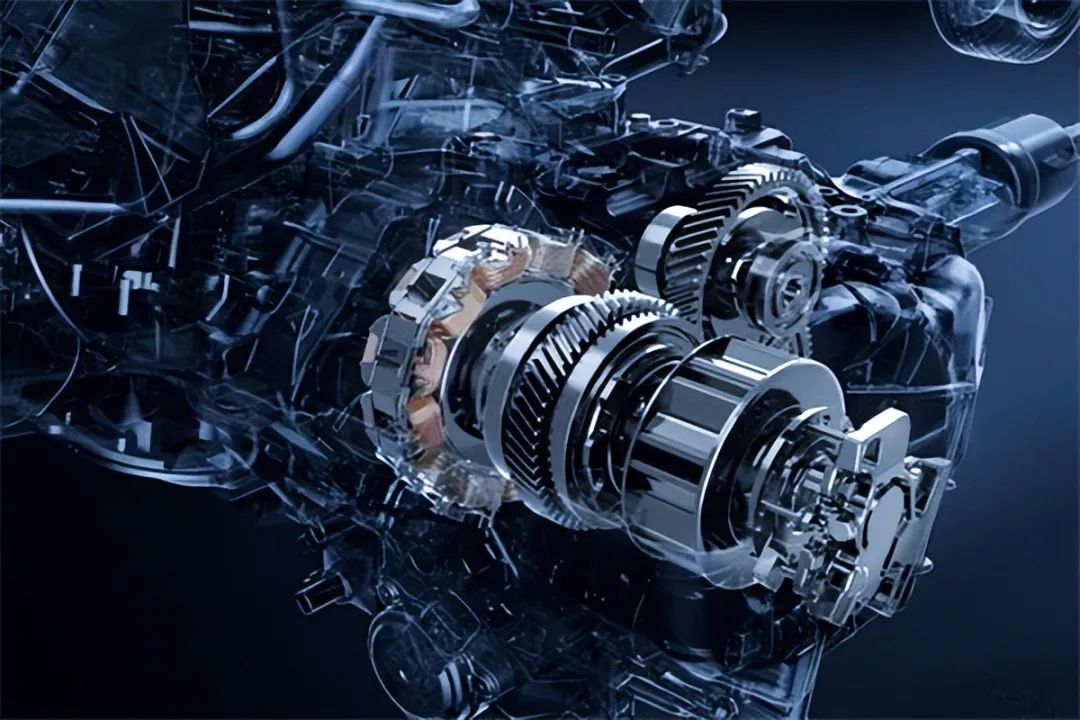

Q10:Will screw valves be used in components such as self-driving cars?

A:Depending on the specific location, glue is required to fix the stator coil part of the motor after it is finalized. In fact, the screw valve itself has a wide range of applications. No matter which aspect it is, it is needed. It just depends on the customer's glue volume (demand). We can use it for anything that requires precise control.

Q11:Will there be any upgrades and updates for screw valves in the future?

A:Upgrades and updates only address the shortcomings of existing products, but what we are more interested in is solving the problems of different displacements, which is a new product. The closer the displacements are, the better the accuracy and the longer the product life. The existing product line cannot meet all customer needs. They may have smaller or larger requirements, or intermediate sizes. This is our focus in the future. If updates are required, different modules may be added to the front or end of the valve to meet the needs of specific occasions.。

Q12:How to collect glue in screw valve?

A:This problem is connected with the previous update. When the screw valve is used in high-tempo glue lines, or when the glue outlet is long, the glue cannot be collected in time. In this case, it is necessary to add a one-way valve or a cut-off module at the glue outlet end. , similar to adding an auxiliary switch, both single liquid and double liquid are available, but of course their expressions are different.

Q13:The glue valve I purchased is leaking. How to solve this problem?

A:This situation needs to be looked at separately and has nothing to do with the product itself. It may be that the viscosity of the glue is relatively low and the needle is relatively thin, resulting in a relatively long glue flow at the front end and a high internal pressure. After one turn, the glue in the hose is not drained and continues to drip. The farther the front-end rubber path is from the stator and rotor, the more difficult it is to control. The inspection can be divided into four steps: first, check whether the valve body fasteners are loose; second, whether there are blockages at the glue supply end and glue outlet end; third, whether there is leakage in the plug; finally, check whether the stator and rotor are leaking. There is wear and tear.

Q14:Is uneven glue dispensing the same as dripping?

A:Differently, if the glue discharge of the valve is not smooth or even after being used for a period of time, on the premise of ensuring that the glue supply end and the glue outlet end are fault-free, it may be that the glue path is blocked somewhere, or the stator and rotor are worn. It is necessary to re-confirm the use environment and scene, as well as the glue composition, so as to adjust the stator and rotor gap and material. For example, it is possible that there is foreign matter in the glue and the stator and rotor are damaged. So this is just a fault, we can handle it, including dripping and other problems. We can also help customers solve it.